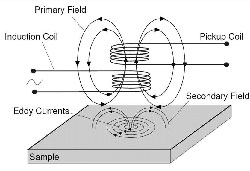

Our technicians conduct inspections of all kinds of industrial equipment and structures using a range of Non Destructive Testing (NDT) methods. We operate in accordance with international standards with a client -accessible database of inspection records. Mainport Kenya is proud to have achieved Full Member Status with the Lifting Equipment Engineers Association.

We conduct Inspection and Load Testing of Lifting Equipment and NDT inspection of OCTG downhole tools and well casings. Our inspectors are qualified up to Level 2 and Level 3.